DIGITAL SOLUTIONS

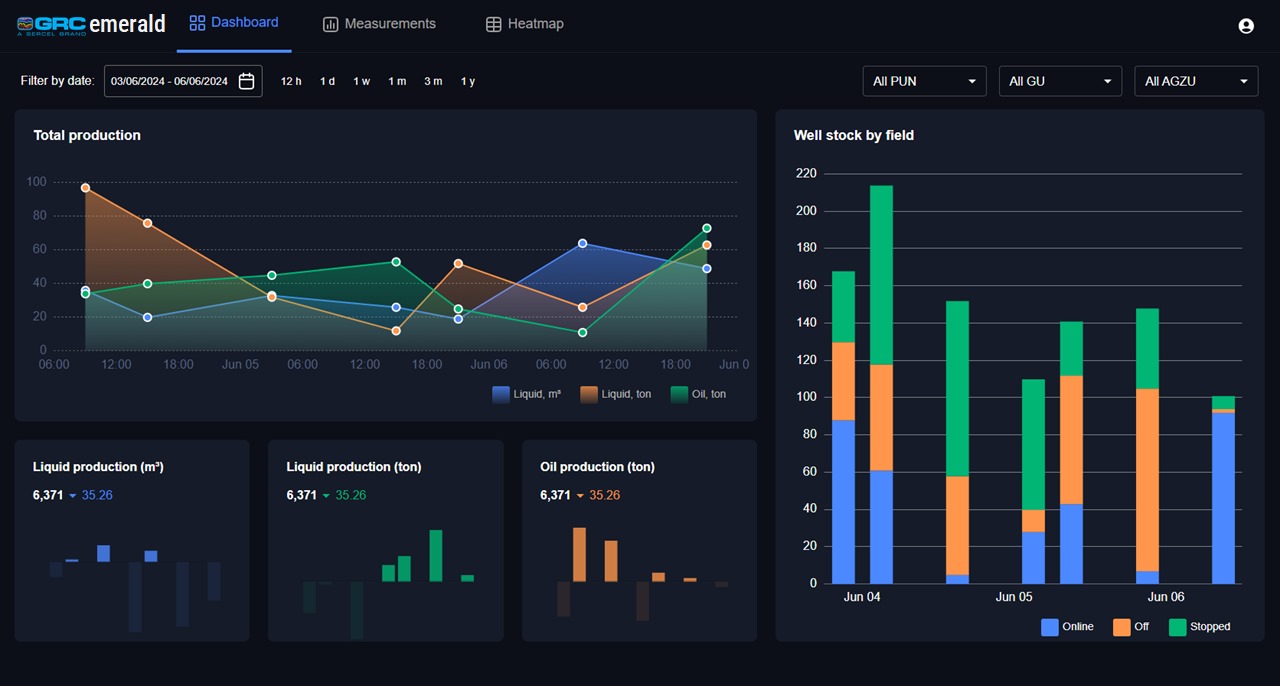

Production Monitoring and Optimization

Emerald represents an oil and gas production monitoring and optimization platform, that harnesses the power to automate and optimize operations for all lift types. Maximize artificial lift run life, improve production, efficiency and reduce downtime with real-time analytics and physics based modelling. The platform is designed by production, reservoir engineering and software/embedded systems experts and is enriched with API calculations and engineering algorithms.

Detection of Anomalies and Threats

Production Allocation

Elevate your operations with Emerald today. GRC’s Artificial lift experts with many years of experience in Production, reservoir engineering, software developers with embedded systems knowledge can help build customized solutions for your operations.

- Eyes to the field

- Maximize work efficiency

- Obtain timely detection and resolutions to operational threats

- Doing more with less

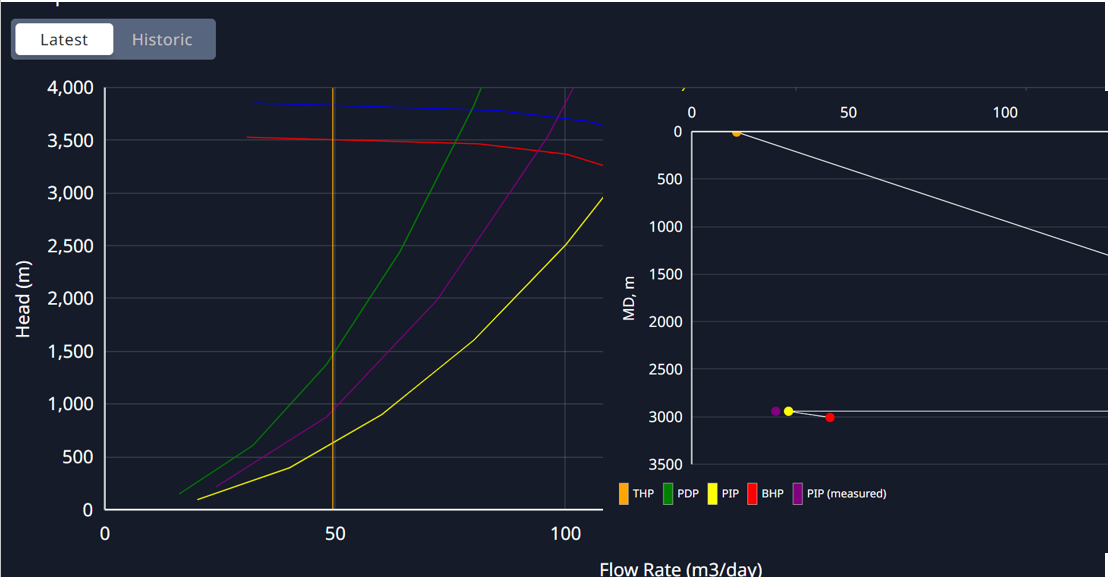

Rigorous Real-time Diagnostics

Electrical Submersible Pumps

Could there be any issues arising from your ESPs?

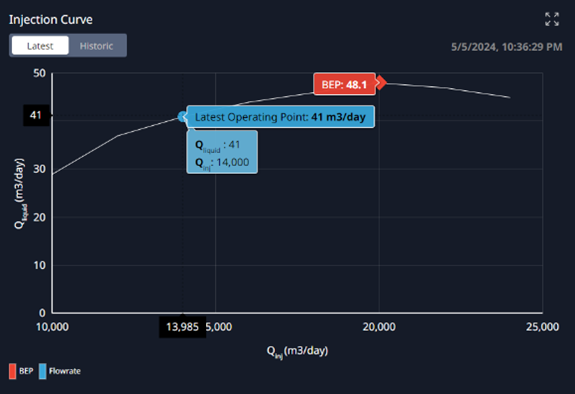

Gas Lift

Are you over injecting?

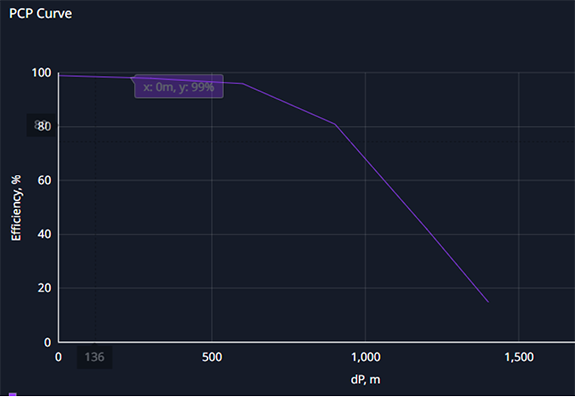

Progressive Cavity Pumps

Is your elastomer okay?

Sucker Rod Pump

Is your rod buckling?

Emerald Edge FAQs

1. What is Emerald Edge?

Emerald Edge is a cutting-edge solution designed for Artificial Lift Well Operators, providing real-time monitoring and remote control to optimize production and extend the life of existing assets. It integrates with SCADA systems and utilizes cloud hosting for efficiency.

2. How does Emerald Edge help reduce OPEX?

Emerald Edge helps reduce operational expenses (OPEX) by providing more efficient data management and streaming; as well as control and monitoring of pump-off operations, leading to energy savings, fewer manual interventions and optimized performance.

3. Is Emerald Edge easy to install?

Yes, the Emerald Edge system is designed to be easy to integrate with existing infrastructure, minimizing distruption to operations during installation.

4. How does cloud hosting improve the performance of the Emerald Edge system?

Cloud hosting ensures that data from Emerald Edge is stored securely and accessible from anywhere. It allows for scalable solutions, quicker data processing and real-time insights.

5. Can Emerald Edge help in optimizing production for any type of well or just specific ones?

Emerald Edge is built to be flexible and can optimize production across various types of Artificial Lift systems, making it suitable for different well configurations.

6. What makes the partnership between GRC and UPC Global significant?

The partnership brings together expertise from both companies, combining GRC’s technical innovation with UPC customer service excellence. This collaboration ensures that Emerald Edge is a highly effective solution for well operators.

7. How does Emerald Edge benefit SRP and marginal wells?

Emerald Edge is specifically designed to optimize operations for all types of SRP (Sucker Rod Pump) systems, including marginal wells. It helps increase efficiency, reduce downtime and maximize production, making it ideal for these high-potential but often underperforming wells.

8. What other applications can Emerald Edge be used for besides SRP and marginal wells?

Emerald Edge is a versatile solution, now available for Gas Lift Optimization. Its flexibility allows it to maximize efficiency across a wide range of technologies in the oilfield.

9. How does Emerald Edge improve the performance of Gas Lift systems?

Emerald Edge integrates with SCADA and cloud hosting systems to provide real-time monitoring and remote control, optimizing the performance of Gas Lift systems. It reduces OPEX, maximizes production and extends the life of these assets.

10. How can I get started with Emerald Edge?

To get started with Emerald Edge, you can contact our partners at GRC by emailing kendall.parker@sercel.com for more information on installation, pricing and further product details.

Edge IoT

Features

- Real time alerts and alarms

- Customized to your hardware requirements

Specifications

- Connections: Modbus 485/232. 4G Cellular modem, LoRaWan radio.

- Enclosure IP 67

- Wall/magnetic mount

- Operating temp: -20 to 70 C

- Analog Sensors: 4-20 Ma

- Optional connections: up to 16 simultaneous Modbus devices scan

- Control equipment onsite: 3 Relay Outputs to control motors, light and other equipment.

- 10 Discrete inputs to read buttons, power and leakage indicators, etc.

Want to Learn More?

Contact our team of experts through our website.