GAS LIFT, PCP, SRP

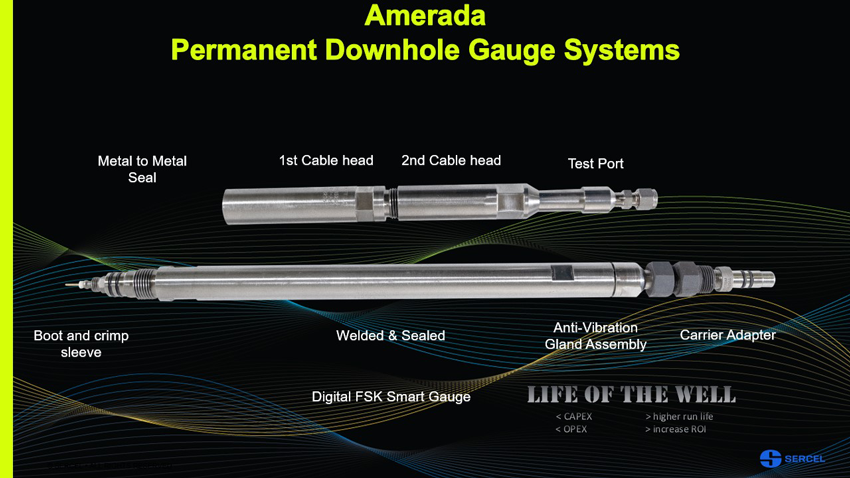

GRC’s PDHG systems are comprised of a unique mechanical concept, with electronic features and channels of fit-for-purpose data.

Optimize Pump Performance, Run Life and Oil Production, and Protect Your People, the Pump and the Reservoir

Sercel-GRC’s Piezo Series of gauges enable monitoring capabilities during the pre-production stages of a typical gas lift, progressive cavity pump (PCP), or sucker rod pump (SRP) well. Our permanent downhole gauge (PDHG) systems offer the long-lasting, robust design of a typical offshore permanent gauge at onshore market prices.

GRC’s PDHG systems combine a unique mechanical concept, with electronic features and channels of fit-for-purpose data. Our systems extend the monitoring capabilities of a typical PDHG sensor to serve a complete cycle of monitoring application needs required during the life of the well when paired wth te proper surface acquisition unit.

The GRC Permanent Downhole Gauge System comprises various monitoring capabilities, including dual pressure on a single assembly; rigless, thru-tubing install; reservoir and well testing; and production capabilities.

GRC Permanent Downhole Gauge System

GRC’s Spy Pro ESP system’s precision welded (sealed) design eliminates the need for re-dressing and contamination. In addition, its shorter, slimline design improves deployment in dogleg severity and rigless applications.

CUSTOMER PAINS

Identifying Your Most Critical Concerns

- Optimize pump performance, increase run life and oil production

- Increase ROI, reduce total operational cost

- Reduce well Intervention parties, risk, liabilities and cost

- Protect your people, pump and reservoir

- Eliminate pump shut down due to sensor troubleshooting

SOLUTIONS

A GRC Data Acquisition Solution for Every Well Application

Gas Lift Optimization

An intelligent surface control and optimization system, incorporating the use of Sercel-GRC’s line of downhole gauges and surface data acquisition equipment, can be used to provide an instant warning of a change in operating behavior in a well, which will allow quick operator action and resolution of optimum production rates. In addition, a normally operating gas-lift system can be continuously optimized by properly allocating injected gas to react to events such as changes in gas-lift supply volume, changes in manifold pressure, or water cuts.

Progressive Cavity Pump (PCP) Optimization

Monitoring downhole pressure data can increase pump speed to keep reservoir pressure down and allow for optimal production. Installing a GRC downhole gauge allows the customer to monitor reservoir fluid level and prevent damage to the downhole equipment by dry pumping. Gauge parameters can monitor pump efficiency and act as an early warning system to prevent premature equipment failure.

Sucker Rod Pump (SRP) Optimization

Increase production by maintaining the lowest possible fluid level over the pump. Avoid premature pump-off due to inaccurate algorithms. Improve control over motor speed by monitoring real-time bottom-hole data. Enable automated decision-making using measurements, not assumptions or calculations. Verify the pump configuration’s actual performance and efficiency. Reduce lifting costs and extend the life of the pump.

View Our Catalog

View or download the full GRC product catalog.